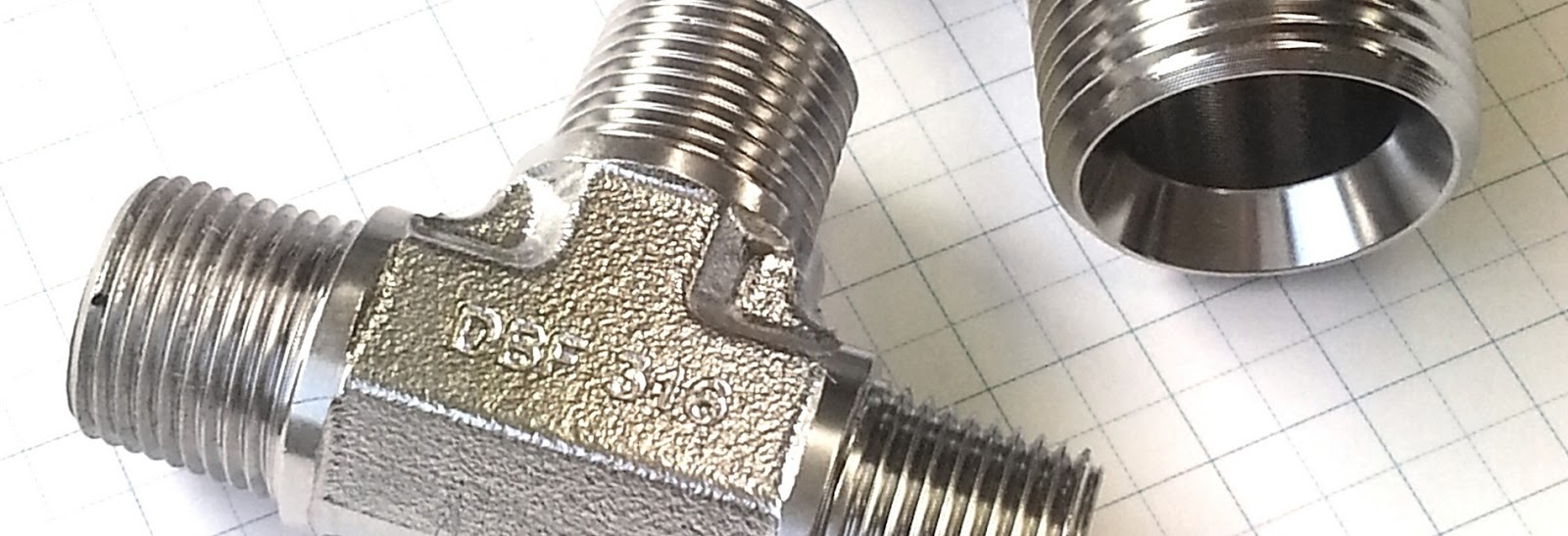

Stainless Hydraulic Fittings

In contrast to plated mild steel, stainless steel boasts a distinctive advantage with its protective layer of chromium oxide. This natural barrier endows stainless steel with exceptional corrosion resistance, making it the preferred choice for applications in corrosive environments.

When you opt for stainless steel hydraulic fittings over their mild steel counterparts, you’re making an investment in longevity. The service life of these fittings significantly surpasses that of mild steel, effectively curbing the need for frequent replacements. This not only translates to cost savings but also minimizes downtime, as you can rely on stainless steel fittings to withstand the rigors of demanding environments without compromising performance.

Why Choose DBF fittings?

Stock Availability

With a vast stock and an extensive design library featuring nearly 4000 distinct items, you can expect almost immediate availability for your requirements. Our commitment to maintaining this comprehensive inventory ensures that your needs can be met without delay.

In the rare instance where an off-the-shelf part is not readily available or your specifications call for a bespoke solution, rest assured that our technical design services and production capabilities are at your disposal. We excel in crafting tailored solutions to address your unique demands, ensuring prompt delivery and complete satisfaction.

Your needs are our priority, and we are dedicated to providing the right solution, right when you need it

Quick Turnaround Times

Get the parts that you need quoted and delivered to you with minimal delays from our in-house design and manufacturing facility. As specialist stainless steel manufacturers, we stock the most extensive range of products available in Australasia. Our team will provide you with same-day quotes and can get orders delivered to you with minimal delay.

Order Reliability

With Australasia’s largest comprehensive range of stainless hydraulic fittings, as well as mild steel connectors, quick-release couplings and valves, processing your order and arranging delivery will mean your business is up and running with minimal delay.

Impulse Tested Hydraulic Fittings

From day one, DBF has prided itself in using only the highest quality raw materials to make stainless steel fittings. To ensure that they conform to the applicable standards, we have invested in a BIMAL impulse testing machine which tests all our manufactured fittings to SAE standards. This is done in conjunction with Gates Hose, to ensure the compatibility and integrity of the fittings to the hose. Therefore, you get compatible assemblies impulse-tested to Internationally recognised ISO6803 and SAE J517 specifications. The size range covered is 1/4’” 1 wire through to 2” 6 wire. Tests are continuous running 24/7 and range from 100,000 to 500,000 cycles.